Equipment

Deodorizer

Gas Scrubber

Final heater

In Aproxar we cover all the specialties present in an engineering project and we develop global criteria services that contemplate the entire structure and adapt to the client.

See our institutional video

News

Engineering

VITERRA Basic and detailed engineering is being developed for vacuum system modification and implementation of economizers to reduce steam consumption in Solvent Extraction Plant of Usti, Czech Republic.

Technical Assistance

BUNGE Evaluation of the biodiesel drying stage at Nova Mutum, Brazil, and diagnosis of the cooling unit for the vacuum system in Puerto General San Martín. GENTE DE LA PAMPA Process adjustments to reduce solvent consumption and decrease fatty matter content in pellets...

Feasibility studies

LDC The investment order and site requirements for the Bleaching and Deodorization unit are analyzed RAMGRAS We develop the technical and economic feasibility of incorporating Hydrogenation and Interesterification units, and the associated tank farm. VITERRA We carry...

Engineering

COFCO Basic and detailed engineering is carried out for the steam distribution and condensate return of the new Toaster in L#1 of Saforcada, as well as the implementation of flash steam recovery. LDC Conceptual engineering is developed for potential energy...

Engineering

LDC A study is being carried out to optimize and reduce steam consumption and effluent generation in Wittenberg – Germany for pre-treatment, biodiesel and pharmaceutical glycerin production units. In addition, improvements are implemented in solvent recovery,...

Technical assistance

AGD We provide support in Refining units in General Deheza with inconvenient for the processing of soybean oil from the new harvest BUNGE We address the need to resolve quality inconvenient in the Puerto General San Martín soybean oil refining unit, and we monitor for...

New customers

We appreciate the opportunity to join as providers of: LARUSO We carried out an optimization study at the oil refining unit in Cañada Rosquín, with immediate implementation of operational improvements. ELEMENTA FOODS Evaluation of business units in Chile. GHEGOIL We...

Production unit

ENERSUR The first turnkey unit is supplied for the production of biodiesel for self-consumption. It will be exported to Paraguay.

Engineering

BIO4 Basic and detailed for the expansion of cooling systems in a bioethanol production unit. BUNGE For high pressure steam piping and new direct steam superheater in Deodorization unit. ENERSUR Basic and detail aimed at expanding the production of bioethanol from...

Field tasks

BUYATTI We solve the problem with the vacuum system in the Deodorization unit. GBE We successfully implemented changes in the process to improve the oil pretreatment and biodiesel washing in order to minimize the presence of phospholipids in the technical grade...

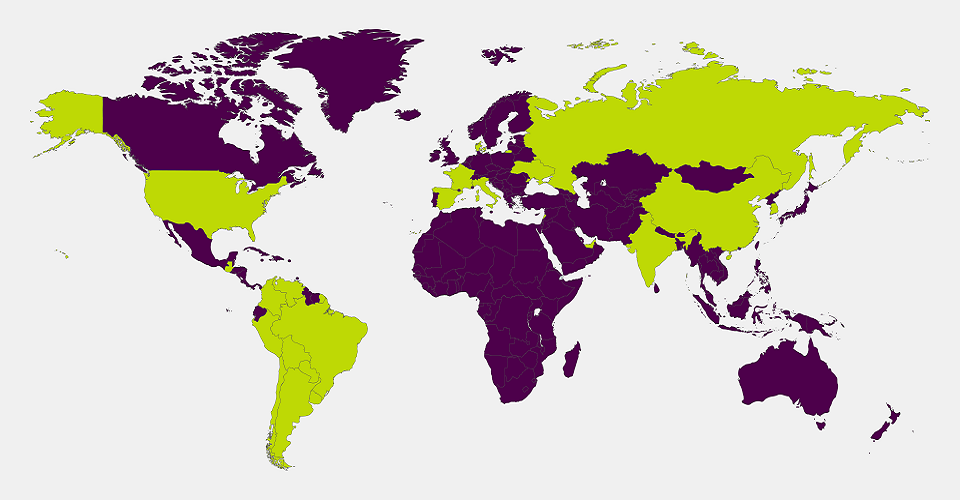

Our Customers