Equipment

Deodorizer

Gas Scrubber

Final heater

In Aproxar we cover all the specialties present in an engineering project and we develop global criteria services that contemplate the entire structure and adapt to the client.

See our institutional video

News

Engineering

LDC We carried out the basic and detailed engineering for the incorporation of an economizer with the gases from the vegetable stripper to preheat the miscella in the 2.100 TPD solvent extraction of rapeseed in Wittenberg, Germany.

Process Assistance

BUYATTI Process adjustments are being made for proper dewaxing at the Reconquista Refinery. COFCO We are providing technical assistance to processes at the biodiesel unit at the Timbúes Industrial Complex. GBE We are conducting a laboratory-scale evaluation of a...

Commissioning

RIS We have successfully completed the start up of the Neutralization and Bleaching units for animal oils and fats, with the option of dewaxing, for 150 TPD. This is part of the expansions to the Villa Rosa Industrial Complex. The engineering for both projects was...

Engineering

COFCO Separator of direct steam for the new Toaster in Saforcada. KENSING Energy integration improvements in Area 500 for tocopherol purification at the Pilar Industrial Park.

Process Assistance

BUNGE Evaluation of the complementary cooling system for the high-vacuum unit in deodorization at the Puerto General San Martín Refinery. BUYATTI Process adjustments to achieve proper dewaxing and improve oxidative stability at the Reconquista Refinery. At the same...

Engineering

VITERRA Basic and detailed engineering is being developed for vacuum system modification and implementation of economizers to reduce steam consumption in Solvent Extraction Plant of Usti, Czech Republic.

Technical Assistance

BUNGE Evaluation of the biodiesel drying stage at Nova Mutum, Brazil, and diagnosis of the cooling unit for the vacuum system in Puerto General San Martín. GENTE DE LA PAMPA Process adjustments to reduce solvent consumption and decrease fatty matter content in pellets...

Feasibility studies

LDC The investment order and site requirements for the Bleaching and Deodorization unit are analyzed RAMGRAS We develop the technical and economic feasibility of incorporating Hydrogenation and Interesterification units, and the associated tank farm. VITERRA We carry...

Engineering

COFCO Basic and detailed engineering is carried out for the steam distribution and condensate return of the new Toaster in L#1 of Saforcada, as well as the implementation of flash steam recovery. LDC Conceptual engineering is developed for potential energy...

Engineering

LDC A study is being carried out to optimize and reduce steam consumption and effluent generation in Wittenberg – Germany for pre-treatment, biodiesel and pharmaceutical glycerin production units. In addition, improvements are implemented in solvent recovery,...

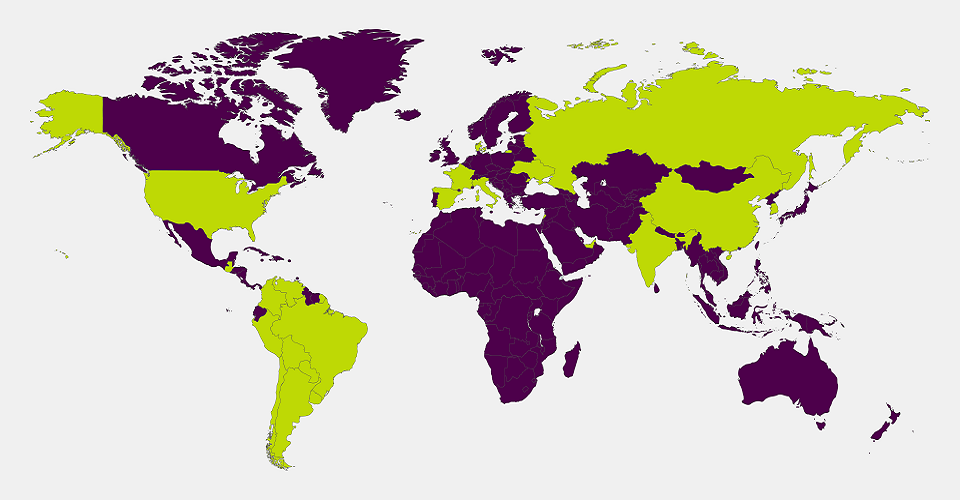

Our Customers